Gold ore flotation machine

Gold ore flotation process plant machine line China Henanmining

Application:of gold ore flotation

Widely used in stone gold such as Sulfide gold quartz vein ore, polymetallic gold sulfide ore, graphite gold ore and sometimes for alluvial gold mine.

Types of gold flotation process

Single flotation, flotation gravity separation, flotation - CIL , flotation - CIP etc and single flotation and flotation - gravity are most popular.

Flow chart of gold flotation

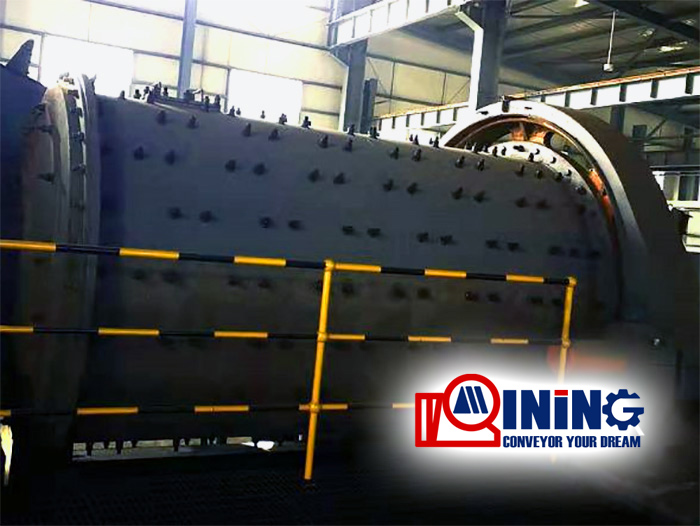

1. Crushing and grinding

First, the ore is crushed into small particles by jaw crusher, cone crusher and counter roll crusher, and then it is grinded by ball mill, usually - 75 μ M 60% - 70% gold can be fully dissociated,

gold ball mill and spiral classifier

2. Mixing and dosing

In the mining agitation tank, adjust the pulp concentration to meet the flotation requirements, and add the required flotation reagents to improve efficiency.

3. Flotation separation

The pulp is aerated in the flotation machine to complete the separation of gold ore and obtain qualified gold concentrate.

Gold flotation machine

4. Tailings treatment

Tailings are dewatered by mining thickener, dewatering screen, cyclone and filter press to meet environmental requirements and then discharged.

Mining thickener

Gold ore flotation machine

Parameter of the Gold ore flotation machine

Gold flotation processing machine

( Take as a reference,for more paraters please contact with us)

| Equipment | Specification | QTY | Power |

|---|---|---|---|

| Jaw Crusher | PEF 500x750 | 1 | 55 |

| Fine Jaw Crusher | PEX 250x1200 | 2 | 45 |

| Swaying feeder | BK600x600 | 1 | 1.5 |

| ball mill | MQY 1800X5700 | 1 | 180 |

| Spiral classifier | FLG-2000 | 1 | 18.5+3 |

| Agitation tank | XB 2000x2000 | 1 | 5.5 |

| Flotation machine | BF-4 | 15 | 15X1.2 |

| Belt conveyor | B500 | / | / |